2024

Focusing On Sustainable Growth With Accountability

Loading

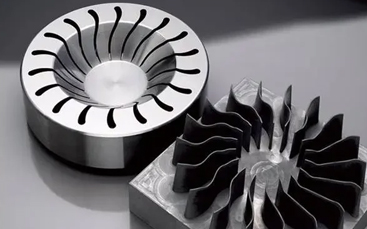

LEECOS boasts extensive experience in machining both metal and plastic parts using CNC turning and milling machines. Based on drawing specifications, LEECOS carefully plans the use of specific machines or a combination of various machining methods, including:

Our components are utilised in industries where precision, Aesthetic and complex shapes are crucial such as aerospace and Measurement segments. Our product range encompasses fittings and fasteners, intricate hydraulic components, and custom electro mechanical parts.

To enhance aesthetics and provide corrosion resistance, the machined parts undergo the following surface treatments:

All raw materials are tested in NABL accredited laboratories before being approved for production. At LEECOS, we handle the following materials in our machine shop:

Throughout the production process, our machined components undergo rigorous quality checks at various stages, culminating in a final inspection. To prevent damage during transit, we pack batch supplies meticulously. Each shipment is accompanied by comprehensive quality documentation, including marked-up drawings, dimensional reports, and material test certificates.

Focusing On Sustainable Growth With Accountability

Entered The US Market And Developed A New Product Line That Is Growing Successfully.

Company Has Become 100% Indian Owned.

Entered Joint Venture With A UK Company— Supplied Aerospace Tools To Rolls Royce, Boeing And Airbus.

Exporting Auto Components: Rocker Arms, Tappets, Hub, Bushes, Etc.